Nitrogen Blanketing Canister

Project aims:

- Transport/store/protect critical spare components for the offshore oil industry.

Project Challenges:

- Challenging variety of environmental issues presented by offshore platforms across the globe.

- Stringent safety standards associated with offshore oil platforms.

Lessons learned:

- Distinction between structural welds and gas retaining welds.

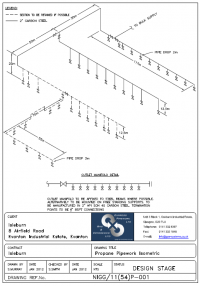

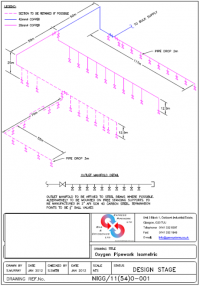

5 System Fabrication Facility – Oxygen, Propane, Argon, Argon/CO2 and Air

Project aims:

- Improve client work efficiency and gas economy with industry leading pipework installation.

Project Challenges:

- Large material quantities transported to isolate site location.

- Scale of system &ndas; 5000m approx. copper, steel, galvinised, stainless pipe system.

- Pipe runs at 25m vertical height.

Lessons learned:

- Importance of pre contract shutdown & planning.

Liquid Nitrogen Fertility Biostore

Project Aims

- To relocate biostore and LN2 Storage to improve user safety

Project Challenges

- Feasible tank location remote from identified biostore location.

- Integration with older LN2 Freezers.

- Transport of biological materials to new location.

Hydrogen Refuelling Station Pipework

Project Aims

- Expand Aberdeen Hydrogen Refueler Network for busses and cars.

Project Challenges

- High specification on electrical and mechanical works

- 900 bar hydrogen system install, testing and commissioning.

- Broad range of electrical and mechanical work.

- Short install window.